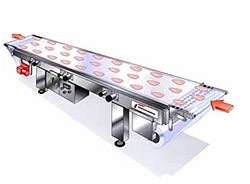

Contact freezers

Contact freezers are made to pre-freeze of lower surface of products which are susceptible to shape change before the final freezing process. The tunnel features a thin polyethylene film conveyor belt. This passes over a plate containing refrigerated pipes and provides one of the fastest and most efficient freezing processes known. This method of freezing is totally hygienic and provides necessary heat exchange between the product and the surface of the contact freezer, which is also an evaporator.

Minimizing the freezing time for the products

It takes 1-3 minutes to freeze an underside of a product to a depth around 1-5 mm, which allows not only save product’s shape, but also reduce time of product presence in a freezer. Contact freeze conveyor can significantly reduce the weight loss of the product, keep the taste and quality of the product, giving you extra manufacturing flexibility.

Hygienic design

Usually contact freezers are used in the production lines after product injection. It’s need to prevent the brine flowing out after injection reduce dehydration of the product, since an ice layer on an underside of the product is formed.

Contact freezers can be effectively used in the production of semi-finished products. Fully stainless steel welded, the contact freezers meets the highest standards of hygiene.

Using environmentally friendly and safe refrigerants

TEHNOMIR company was one of the first in Russia who used energy efficient and eco-friendly CO2 and NH3 as a coolant in its equipment.

If you want to install a shock freeze equipment, send your request or question by e-mail info@tehnomir.biz or call us (812) 346-56-66